As the world grapples with the urgent need to mitigate climate change, the shipping industry is under increasing pressure to decarbonize. Among solutions to improve the energy and environmental efficiency of sea-going vessels, wind propulsion technologies (WPT) present themselves as technically feasible options. These technologies, harnessing the power of the wind, offer a promising and sustainable solution. With recent advancements in technology and design, coupled with a regulatory and societal push towards greener alternatives, the adoption of WPT is poised to play a pivotal role because of the potential of significant savings and environmental benefits for the shipping industry.

Stakeholders are seeking insights into potential savings and guidance on system integration. The performance and feasibility of a WPT project depends on various factors, such as the vessel characteristics, the route, the weather conditions and the WPT design.

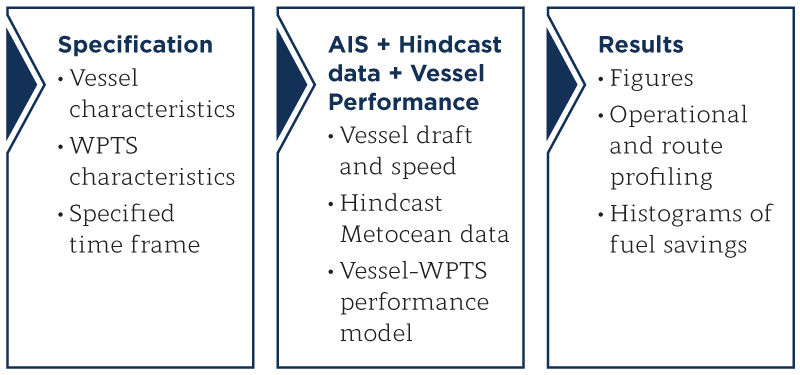

Prediction of Fuel Savings is carried out for a range of specifications: past conditions within a time frame and specified routes and conditions. Hindcast metocean data is utilized to estimate fuel savings. To enable stakeholders to make decisions, ABS applies transparent methodologies for the operational and route profiling and estimation of fuels savings.

HAZID/HAZOP workshops aim to identify, evaluate and control hazards and risks to determine potential problems that may be uncovered by reviewing the safety of WPT design and revisiting existing processes and ship operations. The process requires the engagement of the WPT provider, designer and operator. ABS has an established process with experienced personnel and dedicated tools to meet this scope.

FuelEU Maritime Reward Factor is of interest to stakeholders. As the FuelEU Maritime regulation is associated with a compliance cost, stakeholders are interested in finding out the extent of the discount which may be granted under the regulation in the form of a reward for vessels with a WPT installation. Based on vessel-specific and WPTS-specific information, ABS calculates the prerequisite available effective power Pwind according to MEPC.1/Circ.896, which is used for the derivation of FuelEU Reward factor.

Life-Cycle Cost Analysis is part of the stakeholders’ decision-making process. To derive payback time, ABS is executing the analysis using the supplied input from savings and expenditure perspectives.

Savings:

- Predicted fuel and emissions savings

- FuelEU Maritime reward factor

CAPEX:

- WPT equipment, transportation, commissioning tests, etc.

- Shipyard labor and any work associated with the installation at the location under consideration

OPEX:

- Additional energy required to run the WPT during service

- Additional maintenance

- Training

Vessel Hire:

- Difference in charter rate/fuel consumption