Are there any exceptions in the application of Regulation 3-13?

This regulation does not apply to:

1. lifting appliances on ships certified as MODUs;

2. lifting appliances used on offshore construction ships, such as pipe/cable laying/repair or offshore installation vessels, including ships for decommissioning work,

which comply with standards acceptable to the Administration;

3. integrated mechanical equipment for opening and closing hold hatch covers; and

4. life-saving launching appliances complying with the International Life-Saving Appliance (LSA) Code.

How will the Load Testing and Thorough Examination of Non-Certified Lifting Appliances be demonstrated?

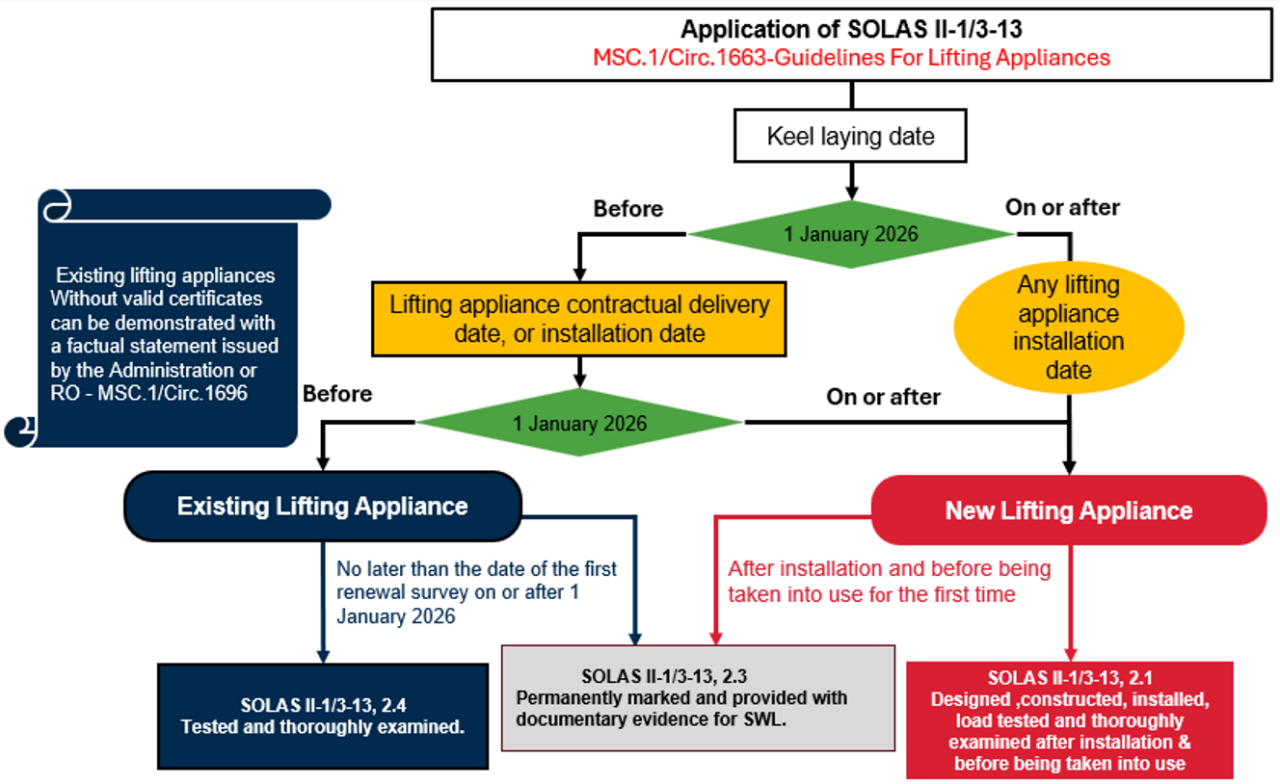

For existing lifting appliances installed before 1 January 2026 without valid certificates of the test and thorough examination under another international instrument (e.g. ILO Convention concerning Occupational Safety and Health in Dock Work (No. 152)) acceptable to the Administration, compliance with SOLAS regulation II-1/3-13.2.4 could be demonstrated by means of a "factual statement" (also known as a "statement of fact"), issued by the competent person approved by the Administration, or the recognized organization (RO).

The factual statement should confirm that the lifting appliance has been subjected to a load test (the value of the test load is to be taken as per table 1 of paragraph 3.2.1.5 of the Guidelines for lifting appliances (MSC.1/Circ.1663) and subsequently been thoroughly examined by the competent person approved by the Administration, or an RO, satisfying the requirements in SOLAS regulation II-1/3-13.2.4 only. The criteria against which the load test and thorough examination have been carried out should be clearly stated in the factual statement. It should further be stated that the factual statement does not confirm compliance with SOLAS regulations II-1/3-13.2.1 and 3-13.2.3. A sample factual statement is provided in the appendix to MSC.1/Circ.1696.

For existing vessels is this just a matter of reissue of the ILO 152 certificate under a new SOLAS format certificate?

For existing lifting appliances with valid certificates, paragraph 3.3.3 of the MSC.1/Circ.1663 states that existing lifting appliances with valid certificates under other international instruments shall comply with SOLAS regulation II-1/3-13.2.4. Acceptable instruments may include the ILO Convention on Occupational Safety and Health in Dock Work (No. 152)

For existing lifting appliances without valid certificates, the MSC.1/Circ.1663 do not specifically address these appliances, except that paragraph 3.2.1.2 mandates load testing for all applicable lifting appliances. Documentation as per the draft unified interpretation mentioned in the question 2 above can serve to fulfill the requirements for those lifting appliances installed before January 1, 2026.

Are Lifting Appliances with SWL < 1,000 KG subject to SOLAS II-1/3-13.2.1 and 2.4?

The Administration shall determine to what extent the requirements do not apply to lifting appliances which have a safe working load below 1,000 kg.

Up to date the following Administrations have advised their position on the applicability of the Regulation to lifting Appliances with SWL less than 1,000 kgs.

It is advisable to consult the flag Administration of the vessel.

What information is included in the certification of testing and thorough examination of lifting appliances?

A sample format is provided below:

What information is included in the certification of test and thorough examination of loose gear?

A sample format is provided below:

What information should be included in the register of lifting appliances and cargo handling gear?

A sample format is provided below:

What information is included in the load testing and thorough examination of non-certified lifting appliances be demonstrated?

What are the relevant References?

More information can be found in the following documents:

- ABS Publication No. 152 - ABS Guide for the Certification of Lifting Appliances

Are lifesaving launching appliances complying with the International Life-Saving Appliance (LSA) Code, explicitly excluded from the scope of these requirements?

SOLAS Regulations II-1/2 and II-1/3-13 do not apply to life-saving launching appliances complying with the International Life-Saving Appliance (LSA) Code. However, there have been suggestions/proposals for Lifting Appliances of Dual Use (serving both as lifting appliance and launching of LSA e.g. survival craft, rescue boat) to be included in the spectrum of the new Regulation provided these appliances comply with the requirements of both instruments i.e. SOLAS Ch. II-1/3-13 and SOLAS Ch. III/LSA Code, and under the condition that both functions are not used simultaneously with the function under SOLAS Ch. III/LSA Code having priority over the lifting appliance function.

Which lifting appliances are considered as “installed” and therefore within scope of SOLAS Regulations II-1/2 and II-1/3-13?

As per the new Regulation II-1/3-13 (effective from 1 January 2026), the term "installed" refers to lifting appliances that are permanently affixed to the ship's structure (by welding or bolting) or permanently travel on fixed rails onboard. Examples include engine room monorail trolleys with hoist (both permanently installed) and lifting platforms for cargo or personnel. Removable or portable appliances are not considered under the scope. Examples include any pad/lifting eyes (usually fitted in E/R) and chain or rope hoist trolleys temporarily mounted on runway beams.

Are the following lifting appliances being excluded from the scope?

Lifting appliance within scope of SOLAS Regulations II-1/2 and II-1/3-13 means any ship's equipment used for cargo loading, transfer or discharge, for raising and lowering hold hatch covers or movable bulkheads, for launch and recovery of tender boats and similar applications, or used as engine-room cranes, stores cranes, hose handling cranes and personnel handling cranes. Therefore:

1. Steering Gear Room Davit: Fall under SOLAS II-1/3-13 if it is permanently installed and used for lifting operations

(e.g., motors, pumps).

2. Sludge Handling Davit: Fall under SOLAS II-1/3-13 if it is permanently installed.

3. Suez Canal Searchlight Davit: Does not fall under SOLAS II-1/3-13, unless it is also used for cargo or stores lifting.

4. Bunker Hose Davit & Bosun Store Davit: Both fall under SOLAS II-1/3-13 if they are permanently installed.

5. Pump Room Davit – Personnel Handling in Emergency: Falls under SOLAS II-1/3-13 if it is permanently installed

and in certain emergency situations may be used to lift personnel (e.g., rescue from confined space).

Does +3M window and 3M extension apply to the Annual and 5-yearly Lifting Appliances surveys?

SOLAS II-1/3-13 and guidelines per MSC.1/Circ. 1663 do not consider window or extension to the Annual and 5-yearly survey.

Should the Lifting Appliance surveys be harmonized with the rest of the statutory surveys?

Harmonization is not mandated. However, if the corresponding Lifting Appliances survey for the year has not been carried out at the time of the SOLAS Cargo Ship Safety Construction (SLC) or SOLAS Passenger Safety Ship (SLP) surveys, the SLC or SLP surveys cannot be completed.

Can the SLC Renewal or SLP surveys on/or after 01 January 2026 be completed without the Lifting Appliance compliance survey being carried out?

SLC or SLP surveys cannot be completed in such a case.

After compliance with SOLAS II-1/3-13, can the subsequent periodical SLC or SLP surveys be completed if the Lifting Appliance surveys have not been carried out?

If the corresponding SOLAS Lifting Appliance survey for the year has not been carried out by its due date, the periodical SLC or SLP surveys cannot be completed.

Does SOLAS certification replace ABS Cargo Gear certification?

No. SOLAS in general applies to the vessel and equipment used by the crew and as the Regulation does not define whether it covers the ILO 152 requirements (stevedores), the ABS Cargo Gear Certification continues to apply.

Are extensions or windows allowed under SOLAS?

No. ABS Cargo Gear certification scheme recognizes window and extension for the non-ILO gear, but SOLAS does not have the same provisions for window/extension. However, Flag Administrations may accept the ABS Cargo Gear survey and certification scheme.

What does “installed on/or after 01 January 2026” mean?

It refers to installation on ships with keel laid on/after that date, or delivery (contractual or actual) of the appliance to the ship on/after 01 January 2026.

Who qualifies as a competent person for surveys?

Competent persons are those with the required knowledge and experience, acceptable to the Administration. IACS RO surveyors qualify and will conduct SOLAS surveys similarly to ABS Cargo Gear surveys.

Who is the responsible person for lifting appliances?

A crew member appointed by the Master or company, trained and experienced in operating and maintaining lifting appliances.

What are the load testing requirements?

Load tests must follow paragraphs 3.2 and 4.2 of MSC.1/Circ.1663, aligned with the proof load standards of the ABS Guide for Lifting Appliances.

What is a Statement of Fact (SoF)?

A statement of Fact is documenting compliance with SOLAS regulation II-1/3-13.2.4 for lifting appliances that do not hold valid certification. The criteria against which the load test and thorough examination have been carried out, are clearly stated in the factual statement. The factual statement does not confirm compliance with SOLAS regulations II-1/3-13.2.1 and 3-13.2.3. A sample factual statement is provided in the appendix to MSC.1/Circ.1696.

Are tender boat davits covered under SOLAS regulations II-1/2 and II-1/3-13?

Yes. Lifting appliances (mainly davits) used to descend/ascend boats that transport passengers or crew between the ship and shore which are not lifeboats (and not subject to SOLAS Chapter III and LSA Code) are to comply with SOLAS regulation II-1/2 and II-1/3-13.

What manuals are required for lifting appliances?

All lifting appliances are required to be maintained, inspected and operated by a “responsible” person. Manufacturer manuals & recommendations, operational instructions/procedures specific to the type of lifting appliance and loose gear inclusive of wire ropes, other industry standards form part of the onboard maintenance plan and are to be available on board. MSC.1/Circ. 1663 provides guidelines for their development should these not be available onboard.