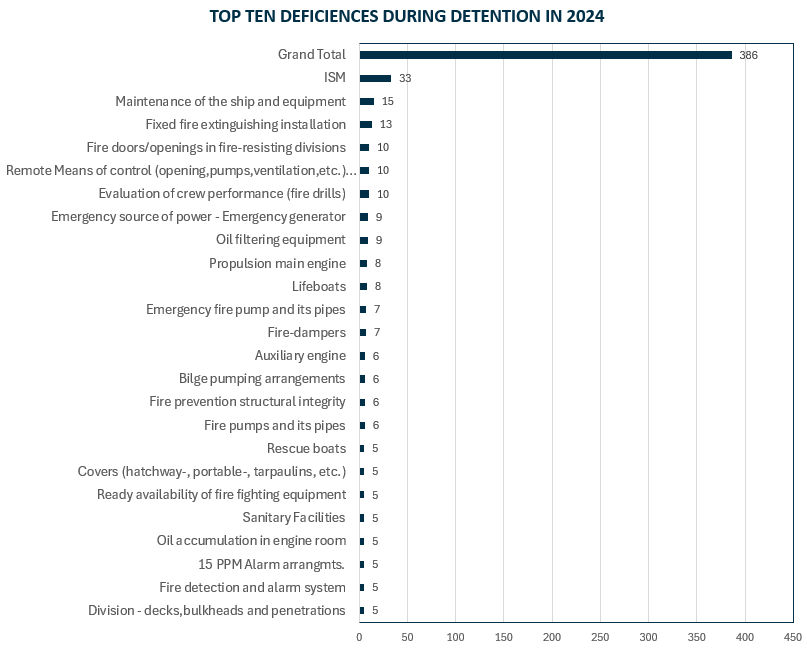

Statutory Certificates, Overdue Surveys

Port State Control inspectors thoroughly review a vessel's certificates and associated documentation to verify that they have been endorsed for all required surveys during the intervals mandated by the various conventions.

The deficiencies found during PSC inspections of a vessel's documentation normally are related to overdue statutory surveys. Surveys must be completed within the required survey window.

Cargo Ship Safety Radio Surveys

The common deficiencies recorded in this category were observed in main radiotelegraph transmission and reception equipment. In some cases, the power output of transmitters was observed to be below an acceptable level, causing a reduction in the range of transmissions. Faults observed in receiving equipment included unsatisfactory reception. Typical examples of other deficiencies in this category were deteriorated aerials; broken aerial insulators; improperly rigged aerials for very high frequency equipment; inoperable automatic alarms; defective speakers; and faulty emergency power sources.

Cargo Ship Safety Equipment Surveys

Lifesaving Appliances (LSA) - The most common deficiencies related to lifesaving appliances were found to be associated with the lifeboats, liferafts and life buoys.

Examples:

- Structural defects in lifeboats

- Lifeboat drain plug missing and/or not attached

- Lifeboat drain plug not marked indicting its location

- Lifeboat windows no longer clear

- Lifeboat hooks incorrectly reset

- Lifeboat crutches not attached

- Lifeboat loose equipment not secured

- Lifeboat compass deviation excessive

- Excessive wear on lifeboat lifting hooks and their attachment

- Safety equipment not in lifeboats

- Lifeboat launching systems inoperative

- Lifeboat engine mountings badly corroded

- Lifeboat engine inoperative

- Life buoy lights not working or missing

- Lifebuoys not fitted with non-kinking line

- Lifebuoy near gangway not provided with light & line

- Lifejacket lights missing and batteries overdue

- Retro-reflective tape missing from equipment

- Float free arrangements on liferafts not satisfactory

- Liferaft painter incorrectly connected to weak link

- Liferaft hydrostatic release unit not indicating expiry date

Fire Suppression and Detection Equipment – equipment must be properly maintained and ready for immediate use at all times.

Examples:

- Inoperable fire pumps (especially the emergency fire pumps)

- Fire main leaking or fitted with doublers or soft-patches

- Fire hoses missing or leaking

- Fire hoses in machinery spaces in excess of 15m

- Defective breathing apparatus

- Fire detectors broken

- No IMO symbols for fire/smoke/heat detectors

- Incorrect IMO symbol for Fire Control Plan

- Fire main isolation valve defective

- Fire detection alarm panel showing zone faults

- Fire-fighters suits incomplete / damaged

- Fire-fighters two-way portable radios missing

- Fire-fighters axe handle not fully insulated

Navigation Equipment and Aids

Examples:

- Missing or uncorrected navigation charts for the intended voyage

- Magnetic compasses requiring repair or correction

- Large bubble in magnetic compass

- Standard magnetic compass with excessive deviation

- Bridge wing repeater not synchronized with master gyro compass

- Faulty echo depth sounders, radars, and navigation lights

- Outdated Tide Tables, List of Lights, and Sailing Directions, etc.

- Copies of regulations (e.g., SOLAS, COLREGS, etc.) not on board

- Battery for Voyage Data Recorder expired

- Notice to Mariners not up to date

- Nautical publications not up to date

- Voyage or passage plan not as required

- Bridge Navigation Watch Alarm System reset button incorrectly located

Cargo Ship Safety Construction Surveys

Common deficiencies found deal mainly with steering gear and mooring arrangement requirements.

Examples:

- Steering control system malfunctioning

- Officers were not knowledgeable about emergency steering procedures

- Communications in emergency steering room not working

- Anchor chains, windlasses, wire ropes and mooring lines were in a deteriorated physical condition and potentially dangerous

- Defective guards on winches and windlasses

- Missing anchors and chain

- Deficiencies with structural fire protection material (oil soaked or missing)

Other deficiencies found, which relate to structural items, are discussed under Classification Surveys, hull.

Housekeeping & Fire Safety, Documentation, Manning, Accommodations

- Manning - The majority of deficiencies in this category relate to the minimum international standards for certificates issued under the STCW Convention.

- Documentation - Deficiencies relate to the vessel's certificates: certificate expired, overdue annual or intermediate surveys, and failure to issue new certificates when a vessel changed flag from one flag to another.

- Accommodations, provisions, and working spaces

- Crew accommodation deficiencies found: infestation by cockroaches, blocked drains; dirty hospitals and bathrooms; toilet piping leaking; shower nozzles and shower controls missing; sinks and toilets broken or not working; crew members living in hospital spaces, doors to accommodations not closing adequately, and light fixtures and switches broken.

- Provision deficiencies related to poor standards of cleanliness. Other deficiencies included in this category are insulation in galleys sufficiently deteriorated to pose a potential health hazard, refrigeration machinery for cooling storerooms not operating properly, and insufficient food for the intended voyage.

- Working space deficiencies found by PSC included lack of adequate lighting and ventilation as well as defective or missing guards to protect the operator from the moving parts of machinery.

MARPOL Surveys

With marine pollution being a major concern, Port State Control inspectors are taking a thorough look at pollution prevention arrangements on board.

Examples:

- Inoperable oily water separator

- Oil Record book not properly maintained

- Sludge overboard lines not permanently blanked or disconnected

- Oily Water Separator (OWS) Unit time not set correctly.

- Three-way valve of OWS out of order

- Sample point of oil filtering equipment not fixed in vertical pipe

- OWS leaking and/or with soft patches

- Missing nuts and bolts on Standard Discharge Connections (Marpol Annex I & IV)

Load Line Surveys

In many cases of PSC detention, the condition of ventilators, air pipes doors and hatchways had deteriorated sufficiently to warrant repair. Many of these detentions could have been avoided by adequate maintenance.

Examples:

- Load Line marks not clear

- Draft marks not clear

- Cargo hatch cover securing devices missing or inoperable

- Sounding pipe caps missing

- Air pipes holed

- Securing devices on weathertight doors missing

- Holes in cargo hatch covers

- Doors or hatches not weathertight

- Manhole covers corroded or bolts missing

- Unsafe external ladders and rails at the side of ship

Other deficiencies associated with the Load Line Convention are discussed under Classification Surveys, hull.

Classification Surveys

Hull - The deficiencies noted in this category were of a structural nature (damaged hull, decks, bulkheads, tanks, etc.).

Examples:

- Damage and deterioration of the hull (included were distorted bulbous bow plating and side shell plating deformations)

- Damaged gang ways, accommodation ladders, deck walkways/platforms, and pilot ladders

- Faulty closing appliances

- Serious wastage, fracture or detachment of hull side frames

- Cracks or wastage of transverse deck beams and deck plating

- Cracks, holes, or severe wastage in bulkheads including collision bulkhead, chain locker, forecastle storage space, and engine room bulkheads

- Vent pipes/closure heads holed or damaged

- Hatches and weathertight doors not weathertight

- Overdue classification survey

Machinery – Common deficiencies for engine rooms.

Examples:

- Inoperable remote controls on boiler safety valves

- Defective fuel oil valves on main and auxiliary engines

- Severe amount of water leaking on auxiliary engines

- Sea water inlet valves incapable of operating

- Defective generators

- Excess oil leakage from boiler fuel pumps and boiler fuel burners

- Defective fuel oil pumps and air compressors (causing shortage of air for starting main engines)

- Deck hydraulic lines and hydraulic lines for hatches leaking or wasted

- Main/auxiliary engine exhaust leaking

- Engine room fire dampers not closing fully

- Funnel flaps (louvres) not closing fully

- Fire dampers/ventilators not marked ‘open’/’closed’

Download Photo

Download Photo