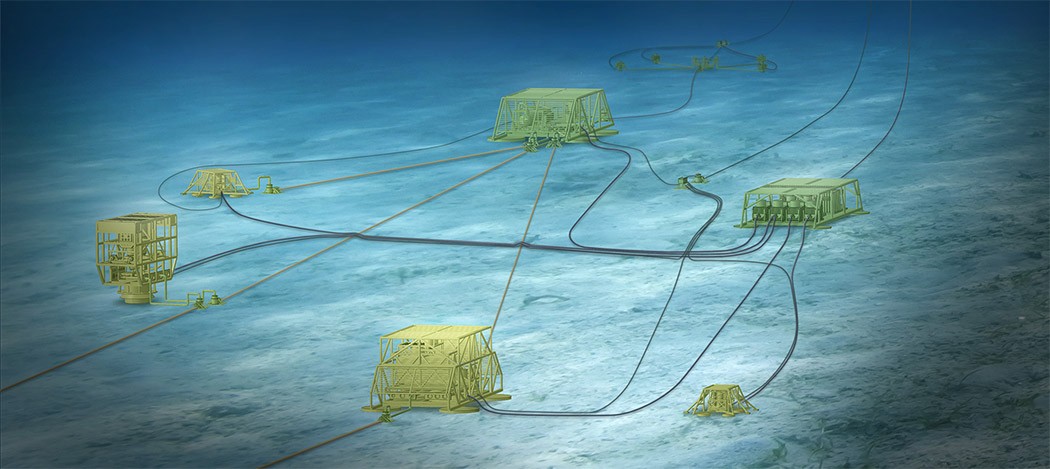

The building blocks of a subsea processing system comprise the subsea separation/treatment system, subsea boosting system, subsea (re-)injection system, subsea power transmission and distribution system, and subsea monitoring and control system. Typically, an SPRS will at a minimum include a subsea boosting system and/or separation/treatment system.

As the industry increases reliance on these systems, there are still some technical challenges that need to be overcome before wider adoption is possible. Some of these challenges include the effects of external pressure on SPRS design, long-distance power transmission/distribution, and optimized monitoring and control systems. While the industry is actively addressing these challenges, near-term field applications primarily focus on subsea boosting systems and components for enhanced oil recovery, increasing tie-back distances and extending field life. As part of this effort, ABS is dedicated to supporting the industry by engaging in various R&D activities and industry initiatives to advance the development of subsea processing technologies and their implementation.

ABS is a lead technical participant in the American Petroleum Institute (API) 17X committee that is developing the Recommended Practice on Subsea Pumping Systems as well as other API 17 series committees. ABS collaborated with INTECSEA in the development of the Offshore Magazine poster on 2018 Worldwide Survey of Subsea Processing. This poster is the subsea industry’s most comprehensive summary of activities related to subsea processing operations. ABS is also collaborating on a triparty project carried out at the National University of Singapore (NUS) and funded by the Singapore Maritime Institute (SMI), involving ABS, NUS and University of Houston (UH) to study the Offshore Pipeline Integrity & Risk Due to Natural Induced and Terrain Induced Slug Flow Regime. The study involves the measurement and analysis of the forces and vibration induced by slug flow on pipeline systems.

ABS has developed the Subsea Processing System Advisory that provides an overview of the SPRS and associated sub-systems that are currently available and addresses its current technology maturity level. The advisory also describes the role of ABS as an independent classification society in the verification and validation of subsea processing technologies including new/unproven technologies through the ABS New Technology Qualification services. The advisory is the first in a series of publications planned by ABS over the next few years. Future publications will include guidance notes, advisories and white papers that provide insight on subsea processing technologies.

The ABS Subsea suite of ABS Rules, Guides, Guidance Notes and advisories currently includes: